Log building has a tradition! We as a manufacturer of machines complement this tradition with the latest technology. Thanks to years of experience and constant innovations, our technology for the efficient joining of log house components is state of the art. Numerous companies already trust this and have successfully used our machines. Our customers are well-known companies in Germany and abroad, from the manufacturer of garden and leisure houses to the producer of apartment blocks.

The machines are individually configurable and scalable and are based on the respective requirements of the user. Each machine is assembled individually in our assembly hall, put into operation and tested and checked in a test run. After installation, our systems are ready for use at the customer and can go into production immediately.

Through the use and installation of high-quality components and through our personal commitment to quality for each individual machine, these are absolutely reliable and reliable, which means that the value of your investment is preserved for many years.

We are happy to advise you and look forward to winning you over as a customer!

Machines in high quality & design

Up to date through technical innovations

Precise & exact processing results

Expert knowledge and industry experience

Personal commitment for satisfied customers

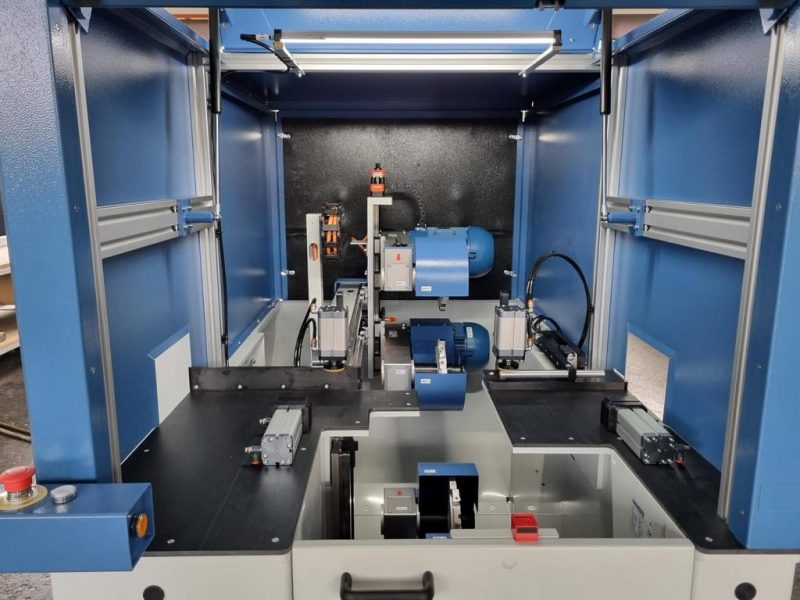

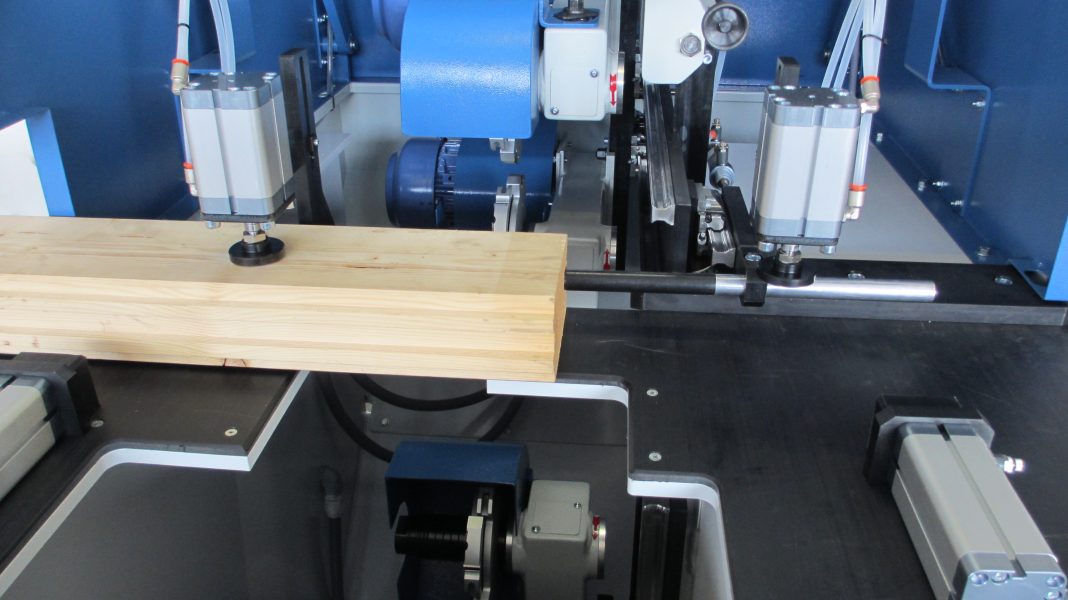

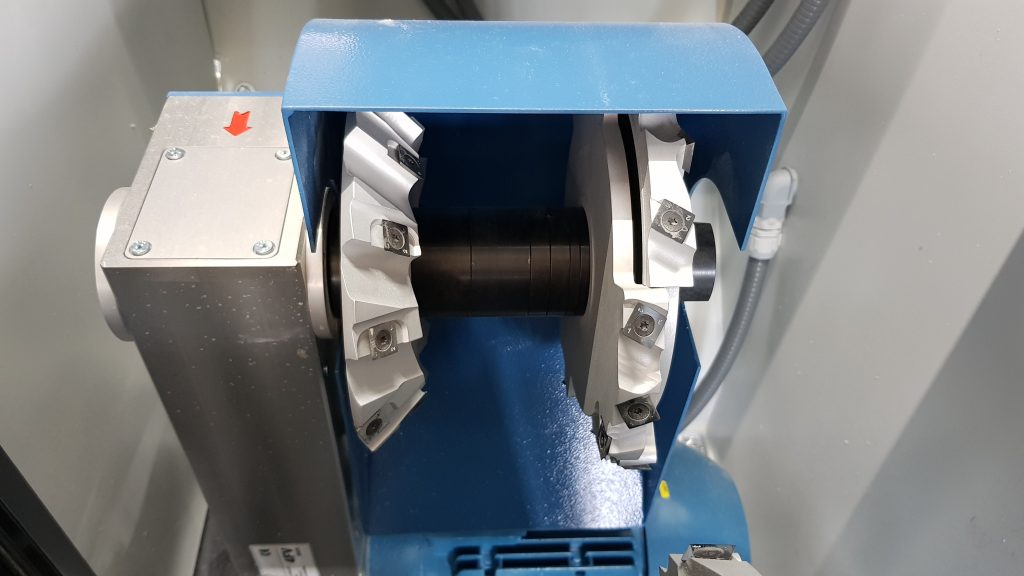

Automatic Blockhausfräse BL100A for the rational production of components for modern log buildings with optimized length cutting, precise milling of the various connections and the creation of bores and bushings.

• Automatic milling depth adjustment of all tools (6 axes in total).

• Precise feed control through servo-electric drives.

• Several other processing options (see processing examples).

• No changeover with different wall dimension.

• Two different wall thicknesses (inner and outer walls) can be produced with one machine setting.

• Production of several components from one raw length in one pass.

• small waste due to length optimization.

• Highest accuracy because the direction of the feed is always the same.

• Maximum performance due to constant work flow up to 150 meters / hour.

• Standard at no extra cost.

• Standardized BTL data import according to the valid data protocol.

• Entering tedious data is a thing of the past.

• Transfer CAD data to the machine – automatically optimize and generate MULTILOG – start production!

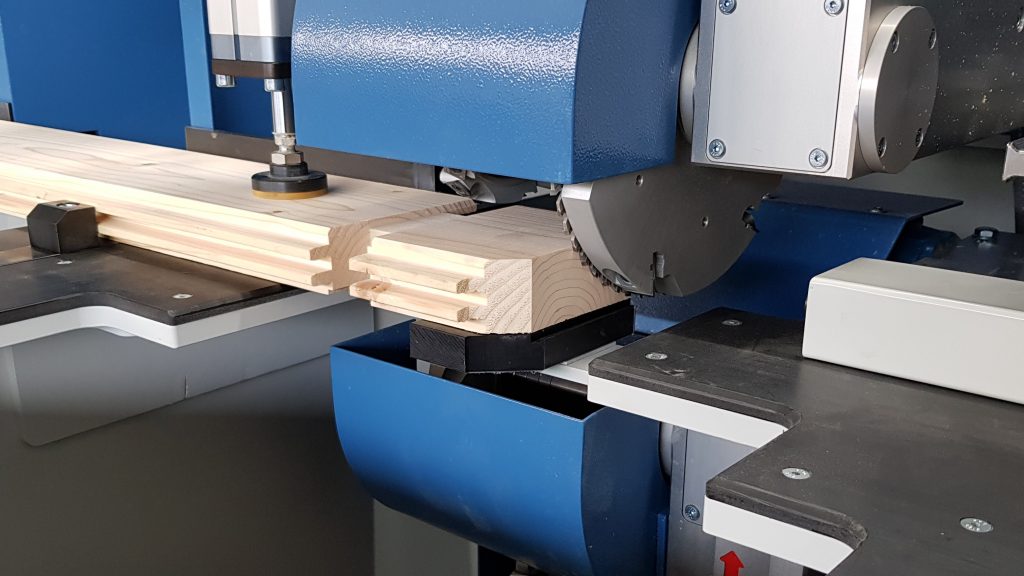

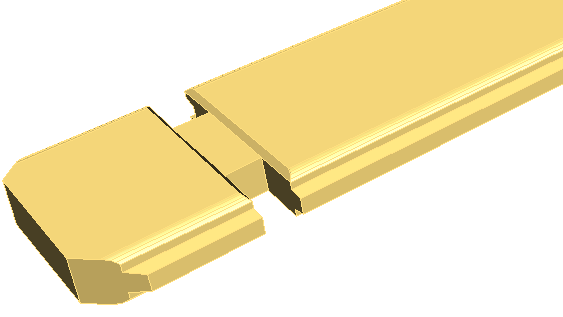

• Dovetail connection for extension or for internal wall connection.

• Dovetail male on both ends of component possible.

• Dovetail female on longitudal or on face side in dimension according to the data input.

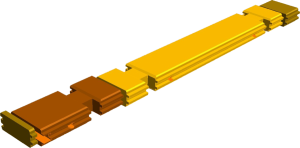

• Tenon and Grooves according to the input dimension.

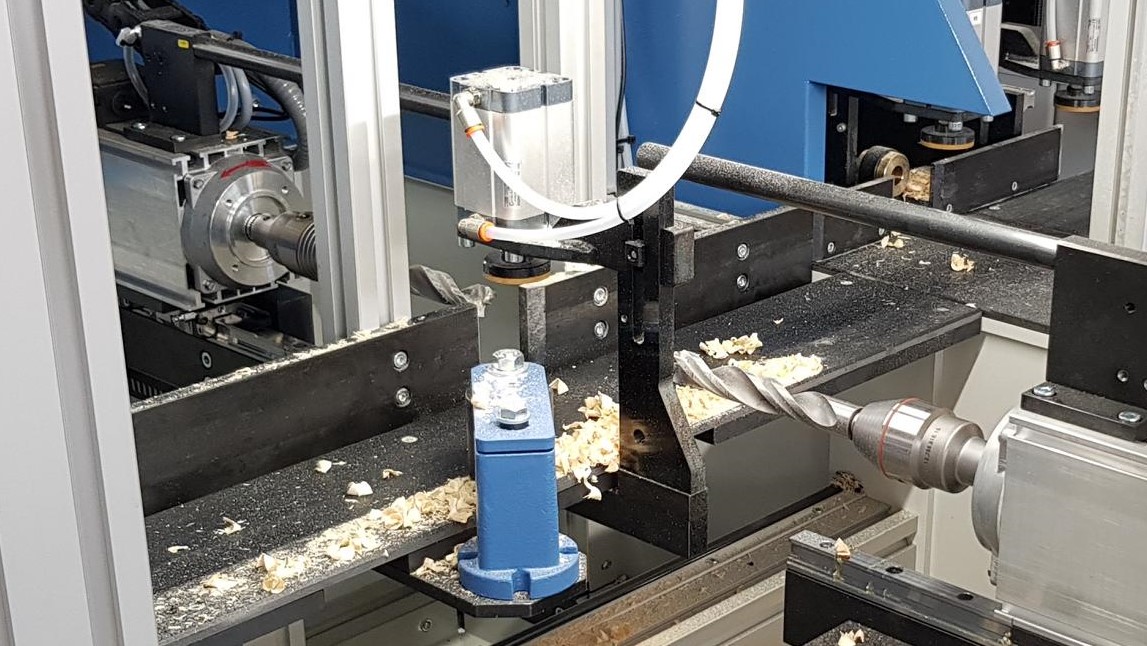

• For the production of numerous bores with high performance and optimal quality.

• Without splittering, as the log is drilled from two sides.

• Two drills can be used side by side and simultaneously, also with different diameters.

• For chamfering the corners on the foreheads.

• Each tool can be used individually, with which each corner can be chamfered individually.

• Programming directly via the software or via data import from the CAD program.

• Splitter free using fine saws combined with profile choppers.

Machine for processing components for modern log house construction with the perfect price level for beginners, small productions or as an complemention for special parts. The components are placed and positioned manually – after starting the processing unit with the 2-hand buttons, the milling process takes place automatically. Optional roller tables and positioning stops are available for positioning the components.

• Component dimension min. 28 x 100 mm and max. 100 x 200 mm

• Component lenght min. 0,30 m – depends on process dimension – and max. according to mechanisation.

With option TS the WP1 machine can be used to mill the Tyrolean lock corner connection by converting the tools and milling templates.

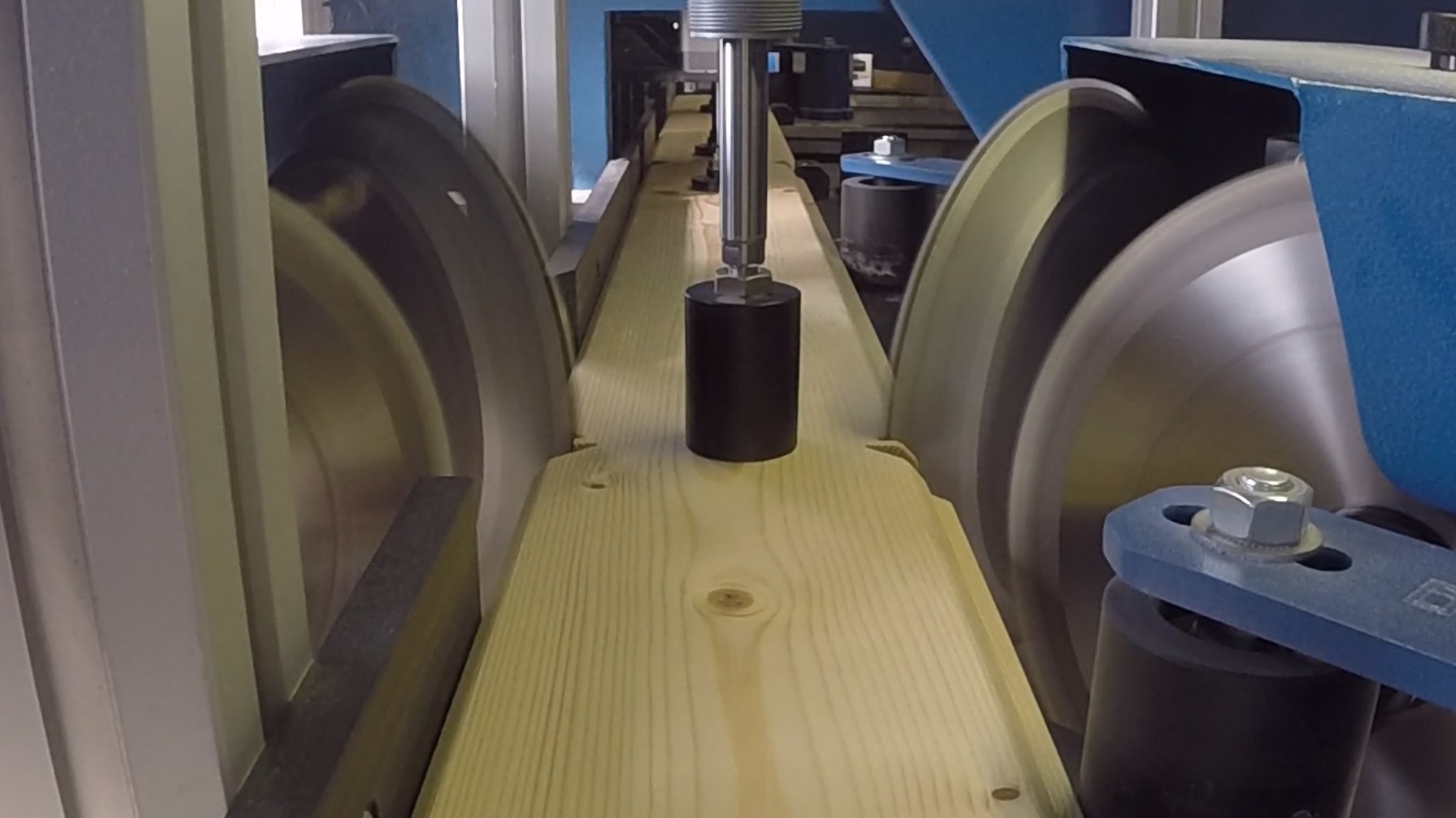

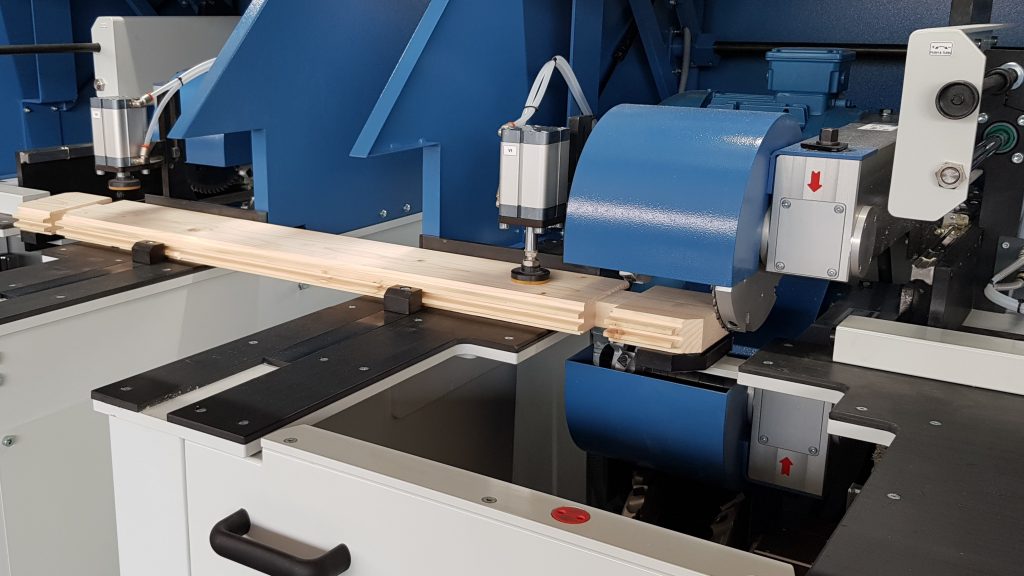

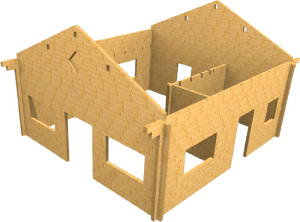

TWIN log house milling machine for the serial production of components for garden cabins. The CHALET corner joint is milled on both sides of the log at the same time. Optionally, 45° chamfers can be milled on the foreheads and the length can be precisely calibrated.

• Component dimension min. 28 x 120 mm and max. 70 x 160 mm

• Component length min. 1,0 m up to max. 6,0m for 2-side processing.

• Component length min. 0,30 m für 1-side processing.

• Automated milling depth adjustment of all tools (6 axes in total).

• Precise feed control through servo-electric drives.

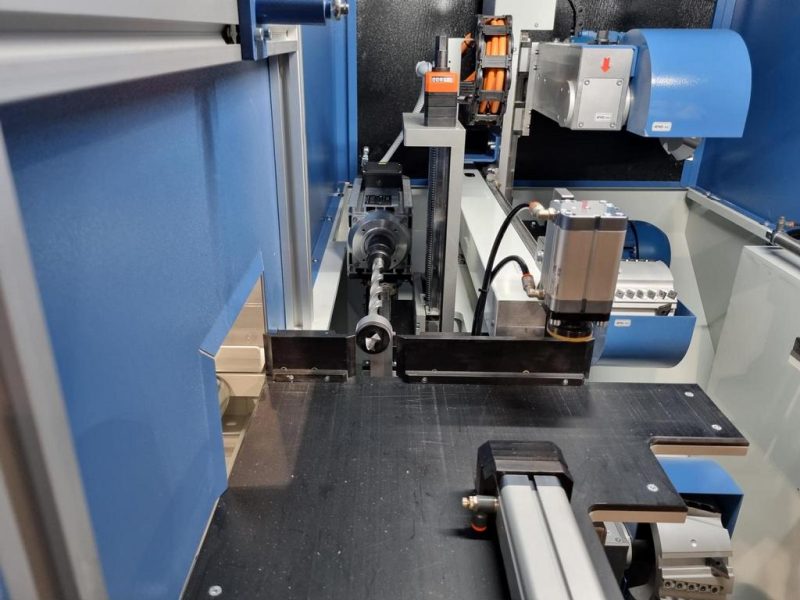

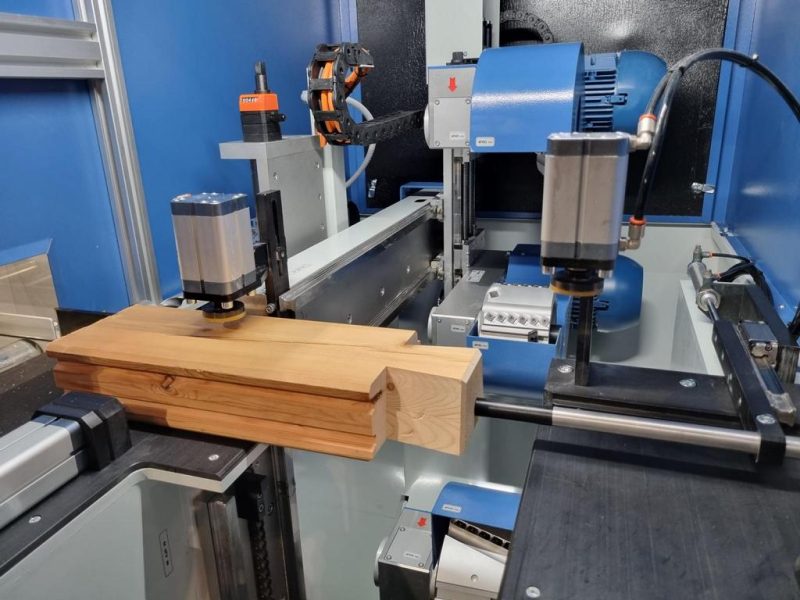

With totally 11 controlled axes and 7 driven tools, the “Tyrolean lock” corner connection with an additional hook connection can be milled in one clamping position in just a few seconds. This ensures absolute precision and a clean corner connection.

• Component dimension min. 70 x 140 mm and max. 140 x 200 mm

• Component length min. 0,30 m (depends on working dimension).

Talk to us – we are happy to answer your questions and look forward to get your message!

Business hours:

Monday to Thursday from 08:00 to 12:00 and 14:00 to 16:00

Friday from 08:00 to 12:00

Languages: ![]()

![]() more on request

more on request

BELGIEN

Lismont R. nv

BE-1480 Saintes

info@lismont.be

ESTLAND

INGELAND

EE-50604 Tartu

dmitri@ingeland.ee

ITALIEN

Rothoblaas KG/SAS

I-39040 Ora / Auer

rothoblaas@tin.it

Tschechien

AGNAR Group s.r.o.

CZ-182 00 Praha

info@agnar.cz

FINLAND

Penope Oy

FIN-15680 Lahti

info@penope.fi

NIEDERLANDE

Tigerstop B.V.

NL-7641 AA Wierden

hhennink@tigerstop.com

GROßBRITANNIEN

JJ Smith & Co Ltd

Liverpool, UK

sales@jjsmith.co.uk